Erik Perkunder is upbeat. But an equipment shortage is holding up a shipment to one of his customers in Hawaii. There are back orders that need to be filled. And the company he helped found has yet to turn a profit. Yet Perkunder and his confederates still break up the workday in their usual fashion, sipping espresso made by a machine they all helped create.

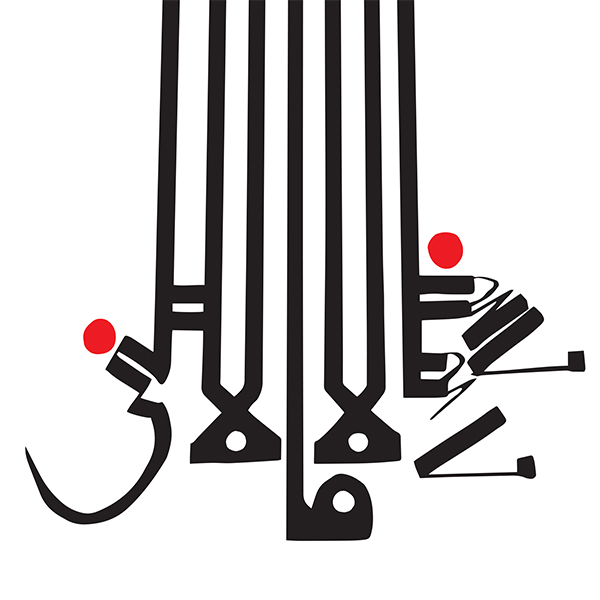

At their digs in the old Rainier bottling plant in Georgetown, Perkunder’s company, Seattle Espresso Machine Corporation, makes the Slayer espresso machine, the current darling of the coffee-fetishizing world and the first of its kind to be designed for the industry’s “third wave,” where bean origin and cultivation are paramount concerns. As Perkunder and the Slayer’s fellow creator, Dan Urwiler, sit nearby, head machinist Devin Walker twiddles the Slayer’s handles in an effort to find the “sweet spot.” This morning’s fare comes from a small coffee roaster in San Antonio, a half-Ethiopian, half-Kenyan blend from which Walker produces a syrupier-than-average pour that is, according to all three men, one of the finer shots of espresso they have ever tasted.

Whereas other espresso machines have fixed settings, the Slayer gives baristas greater influence over the brewing process, allowing them to manually control the water pressure used in extracting the shot—the machine’s main innovation. As Perkunder explains, most espresso makers push water through the grounds with such force that much of the flavor is lost in the extraction. With Slayer, a shot-puller is able to tailor the pressure to the specific coffee, thereby bringing out the best flavor in the single-origin blends now favored by coffee intelligentsia.

Perkunder began conceptualizing what would eventually become the Slayer in 2007. He soon enlisted Urwiler, a prior collaborator. In 2004, the pair helped develop the Treuh espresso machine (now known as Synesso), which was itself an innovation in water-temperature regulation. The Slayer, Perkunder says, represents the next step in espresso technology.

“Many of the older machines aren’t compatible with these unique, single-origin coffees that are available now,” he explains. “They’re part of an antiquated technology designed for an older coffee culture, where the espresso is so strong that it’s all you can do to force it down. We wanted to create a product that would not only make great coffee, but something that would change the dynamic in the industry.”

There’s just one problem: From knobs to steam wands, every component of a Slayer is made and assembled by hand, making production a relatively slow, painstaking process and the machines expensive to purchase.

Four months after its debut at the Specialty Coffee Association of America’s exposition in Atlanta, only 20 Slayers have been shipped. The company has about 10 back orders to fill, from such far-flung locales as Australia. But potential customers in traditional centers of coffee culture have been somewhat resistant. At $14,000–$18,000 per unit, the Slayer may be too pricey to spark the paradigm shift Perkunder hopes for.

“People have really grown comfortable in the traditional markets,” says Matt Milletto, vice president and director of Portland’s American Barista & Coffee School. “The espresso machine is the foundation of any coffee retailer. And because it represents such a significant investment, selling someone on some new form of technology can be difficult.” An analogy further illustrates the dilemma: “It’s like shopping for a car; there are Ferraris and there are Toyotas. The Toyotas are great machines and they’ll satisfy those needs, but for a retailer in some competitive market that wants to do something different, a machine like Slayer will be attractive.”

Confirming Milletto’s theory, Perkunder says, “Our market is retailers who are on the very high, very specialized end of the coffee industry. So we become worldwide. There [are] not a lot of other options if you’re doing what we do.”

As such, Team Slayer will be skipping what could have been a fruitful marketing opportunity on Sept. 25, when Coffee Fest 2009 arrives at the Washington State Convention and Trade Center in Seattle. “As of right now, an exhibition space there is a luxury,” says Perkunder.

His alternative marketing strategy: Invite potential customers for a visit and rely on good old-fashioned word-of-mouth. “We’re talking about introducing a new technology to people who have strong opinions on how to brew espresso,” explains Perkunder. “The advantage that we do have is in the drink. It all starts with one sip.”

But even if demand for the Slayer increases, Perkunder has no plans to speed up the company’s already-overburdened production schedule. “We’re a boutique assembly and manufacturing facility; Slayer will never be a mass-produced product,” he says. “But who knows?” he adds with a grin. “I say this now, and in six months maybe we’re out of business.”