Seattle has two seasons. There’s the gray, rainy one, where temperatures are chilly to mild, and there’s the oasis-like, eye-defying summer, where everything is bright and sunny. During the latter, the temperatures can rise to the 80s and 90s. For general enjoyment of life, this is great. But for beer production, it can be trouble.

You’ve probably been at a bar in the summer where the beer is warm and foamy. It’s just a matter of physics: When temperatures rise, beer brewing and beer maintenance have to adjust. But what does that look like? What must breweries do to keep one of Seattle’s most appreciated products safe for day drinking?

“The great thing about warm temperatures,” says Robyn Schumacher, cicerone and co-owner of Ballard’s Stoup Brewing, “is that more people want to get out and drink beer. Our production goes up in the spring and summer, and our taproom and beer garden get even busier. These are all good things, but this means, of course, that we have to adapt production and beer service to accommodate for warmer temperatures and bigger crowds.”

As the temperatures increase, Schumacher and team are cognizant of every detail, from the “ambient temperature” of the room to staying on top of the delicate brewing science of fermentation and precise yeast reactions. “Fermenting beer puts off a lot of heat and can rise beyond temperatures that are best for the yeast and ultimately the flavor of the beer,” Schumacher explains. “Yeast behaves differently at different temperatures and can put off flavor and aroma compounds that, if controlled, are favorable, but if not controlled, can be off-style or just not delicious.”

So Stoup’s brewers control their tank temperatures using jacketed tanks and glycol systems. “Another temperature-related issue is that the city water warms up in warmer temperatures,” Schumacher says. “We use cold water in our heat exchanger to cool down the wort [unfermented beer] from boil kettle to fermenter. The warmer city water means we have to use more water than usual. Luckily, we capture the water and reuse it.”

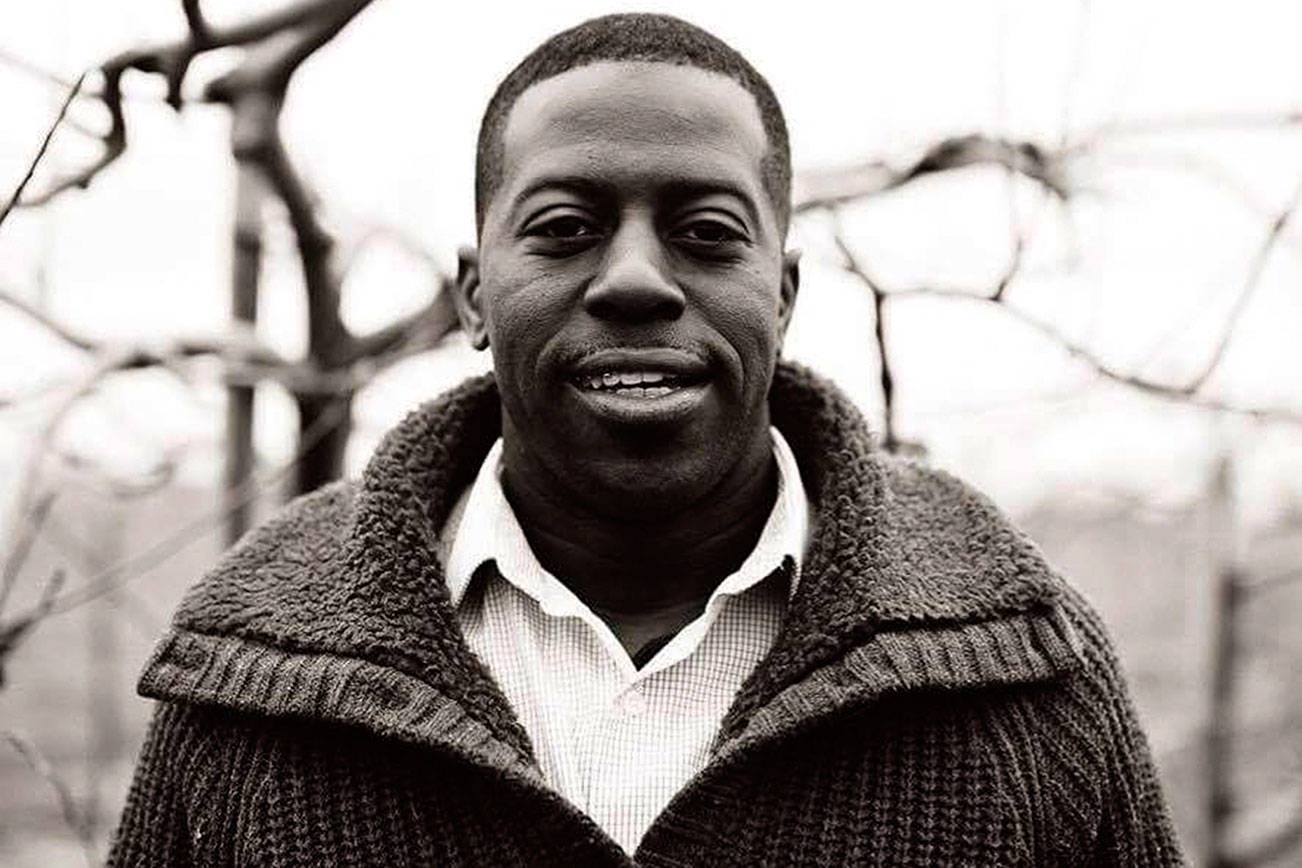

Georgetown Brewing co-founder Manny Chao says he has had to solve issues at bars in the summer when the beer gets too foamy from the heat. “We definitely run into more troubleshooting at bars for foamy beer in the summer,” says Chao. “Usually, coolers get too warm because they are either poorly maintained or the doors are left open.” And while some bars have their kegs directly under their taps, others have them in coolers, sometimes dozens of feet away, requiring long lines to transport the beer. The longer the lines, the more issues that can arise. “Glycol systems usually get stressed too, for bars with long lines,” notes Chao. “Proper maintenance is key.”

But once the beer is brewed, packaged, and served, it’s up to Mother Nature and the drinker. “Once the beer is poured, it’s at the mercy of warm hands and sunshine,” says Schumacher.

beerhunting@seattleweekly.com